As we build a more sustainable future, we must shift how we use resources to ensure both economic growth and environmental preservation. Challenges such as resource scarcity and rising CO2 levels call for change across all industries. Construction, for example, requires a large amount of resources and energy while simultaneously creating an equally large amount of waste and carbon emissions. The traditional linear approach to construction harms our planet. This linear take-and-dispose approach to construction is harmful and unsustainable and requires disruption.

One such disruptive innovation?

Researchers at the Swiss Federal Institute of Technology Zurich (ETH), Nanyang Technological University Singapore (NTU), and Karlsruhe Institute of Technology (KIT) propose a circular model to create new building materials – mycelium-bound composites, or MBCs, out of the virtually limitless amount of agricultural and timber industry waste. This represents a transition from mining for resources to valorising waste, a biocycle from creation to disposal. This shift promises a brighter, greener future for the Architecture Engineering and Construction (AEC) domain. The Urban Biocycles Mycelium Digitalisation (BIO) research module is at the forefront of this paradigm shift. Here, we showcase our most important research findings and highlight the interdisciplinary nature of our BIO research. By combining mycelium-based materials with digital fabrication techniques such as 3D printing and robotic milling, we are pioneering eco-friendly construction. Our research evaluates the lifecycle of MBC through sustainability assessments, benchmarking our impact against conventional alternatives and optimising our production methods. The BIO Lab Table showcases a multi-disciplinary body of work for sustainable building construction at both global and local scales. Using our global research network, in 2023, BIO initiated a wide-ranging investigation into the bio-fabrication potential of MBC. “Metrics for environmental assessment of mycelium-bound composites in construction: A comparative study between Europe and South-East Asia’’ (Regional Comparison Study on MBC) to assess how different substrates impact the mechanical, acoustical, and thermal properties of MBC. Our exhibit’s central column showcases data, analyses, material specimens, and a construction-tailored method for testing MBC for building construction applications.

This study aims to develop a comprehensive, scalable, and open-source set of guidelines encompassing:

- Selection of a mycelium strain that can be acclimatized to different regions

- Development of mechanical testing and analysis protocols for the MBC specime

- Development of a methodology for conducting a meaningful comparison between materials from different regions which require similar but different biofabrication procedures

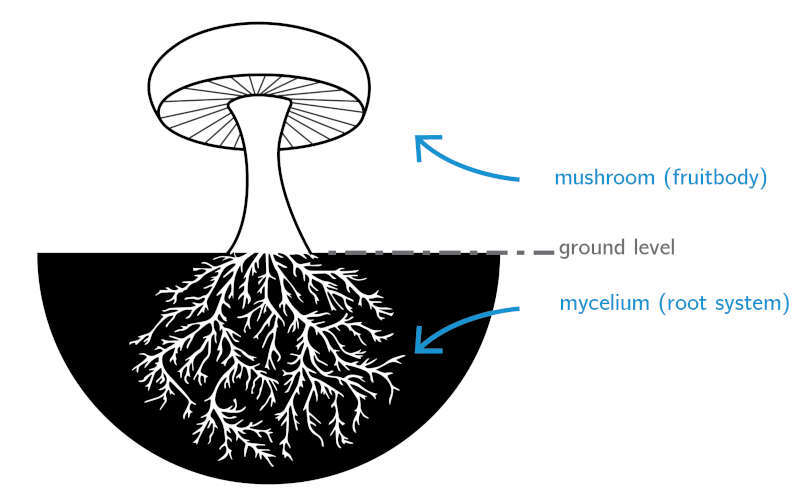

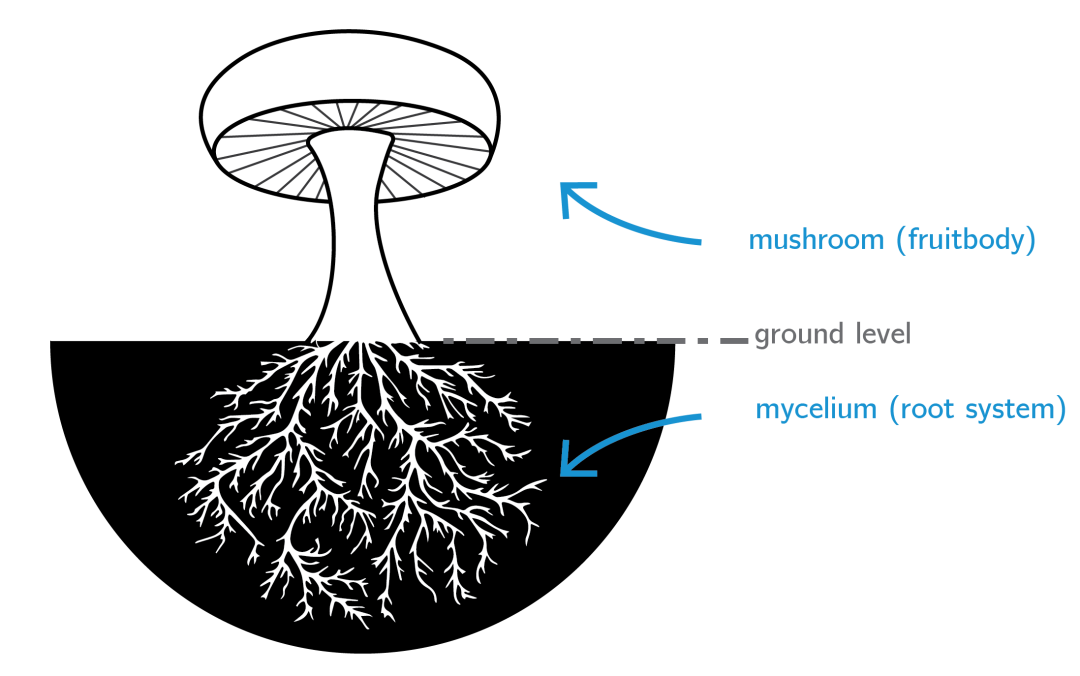

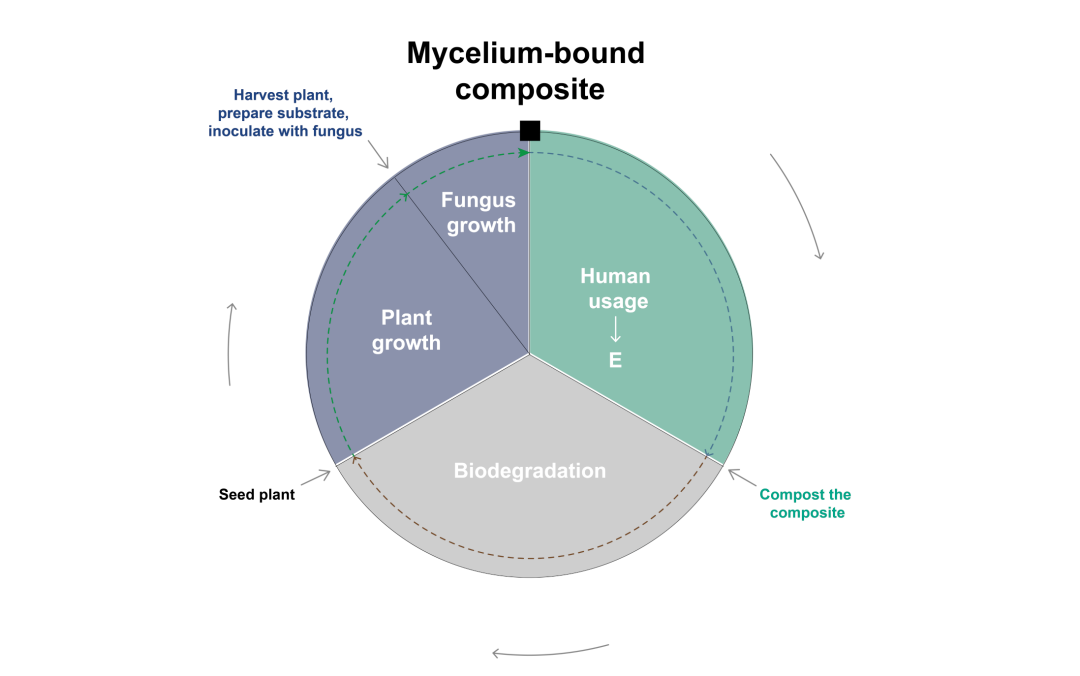

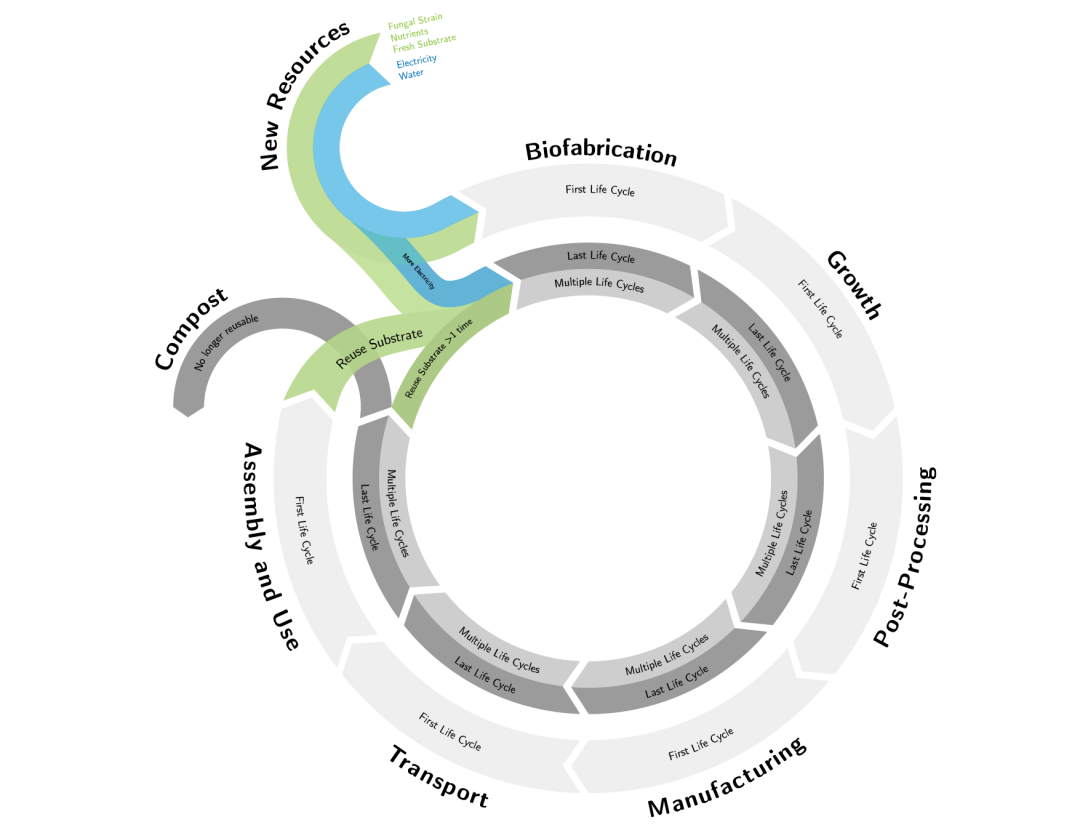

1. Constituent parts of fungi2. Lifecycle of mycelium bound composites (MBC)3. Metrics for environmental assessment of mycelium-bound composites in construction: A comparative study between Europe and South-East Asia

NTU

At NTU, we study the interrelations between the growth process, structure, performance, and sustainability at the microscopic level and its influence at a macroscopic level on mycelium-bound composites. This expertise is reflected in our contribution to the Regional Comparison Study on MBC. Here we biofabricated MBC samples utilizing coconut fibres, specific to South-East Asia.

Growth of MBC

Mycelium growth in composites is governed by factors including nutrient content, water content, and substrate size. Adjusting the nutrient content through the addition of supplements such as oats and malt allows for various growth behaviours of different strains of fungi. Generally, a higher nutrient content results in a thicker and denser mycelium network while a lower nutrient content causes a thinner and sparser network.

Processing of MBC

Mycelium-bound composites of various shapes and sizes can be realized using either 3D printing to print extrudable pastes containing mycelium or 3D printed moulds. The complex structures formed and/or various materials loaded into pastes can be used to control the growth of mycelium throughout the printed structure, thus realizing the concept of mycelium digitalisation.

Performance of MBC

By increasing the porosity of composites, we observe an increased production of mycelium skin thanks to increased airflow through the composite. This results in stiffer composites.

Application of MBC

Bioinspired structures can be developed using mycelium-bound composites, through an investigative process called biomimetics, thus combining the functional advantages of nature with the sustainable aspect of mycelium-bound composites. Mycelium-bound composite tiles inspired by the elephant’s skin can capture water and provide cooling by evaporation, thus providing a promising solution to thermal regulation of buildings and reducing the dependency on space cooling.

DBT

At DBT, we investigate the essential aspects of scaling up fungal-based materials within the AEC industry. The main goal is to identify innovative bio-fabrication methods for prefabricating large-scale Fungi-based demonstrators, leading to real-life applications. Our research focuses on novel bio-based processes tackling essential biofabrication aspects such as scalability, quality control, and thermal, mechanical, and acoustic performance. The research revolves around three core domains:

In the BIO Regional Comparison Study on MBC, we contributed to the selection of mycelium strains and substrates, the development of a unified MBC growing protocol, acoustical and insulating capacity testing, and analysis of the test data for reports and publications.

Fungal Biology Analysis and Material Strength

This area of research comprehensively analyzes fungal-based materials at micro, meso, and macro scales. It encompasses both qualitative and quantitative assessments indispensable for identifying the main factors influencing material strength.

Natural Fiber Substrates Characterization and Design Space

Here, the emphasis lies on innovative additive technology for bioprocessing various substrates. Such processes encompass woven, knitted, and laminated scaffolds using natural fibers such as hemp or flax. These scaffolds or lost molds serve as the basis for enhancing the overall mechanical performance without impeding the good thermal and acoustical performance of MBC.

Controlled Environment Characterization for Scaling Up Manufacturing of Biomaterials

This domain applies to designing and developing novel manufacturing environments to prefabricate fungal-based materials at larger scales.

KIT

At KIT, we focus on improving fungal mycelium growth essential for the development of more competitive MBCs. Our material formulations are specifically tailored to allow the use of advanced digital fabrication technologies such as 3D printing and robotic milling. Our work follows a circular approach to sourcing, utilizing, and disposing of agricultural waste resources promoting eco-friendly building practices. In the BIO Regional Comparison Study on MBC, we contributed to the selection of mycelium strains and substrates, the development of a unified MBC growing protocol, mechanical testing, and analysis of the test data for reports and publications.

Quality control in bio fabrication of MBC

During the initial phase of the BIO Regional Comparison Study on MBC, KIT has assumed the responsibility of refining the methodology and optimizing protocols ensuring both qualitative and quantitative standards are met in the upcoming phases of the study. KIT is researching the optimization of fungal mycelium substrate and growth conditions for large-scale production of mycelium materials.

Scaling up the production and application of MBC boards

Mycelium is suitable for a versatile range of applications with adjustable properties including form, density, mechanical characteristics, and overall performance. These varying properties can be attained through diverse manufacturing techniques and by selecting different substrates and mycelium species. For example, by using hemp hurd as the substrate and Ganoderma as the mycelium species, combined with varying manufacturing processes, we can create composites with densities ranging from as light as 100 kg/m³ to as high as 1000 kg/m³. This broad range of densities allows for applications in the building sector. The lab’s expertise is complementary to that of the three other research groups, leveraging the fundamental research at NTU and being informed by bio fabrication and digital manufacturing methods developed at the ETH.

BRG

At BRG we focus on high-waste, short lifespan applications. As mycelium-based materials are circular, they have the potential to reduce the amount of waste going to landfills in applications such as temporary formwork systems for shell construction and interior partition walls. Designing with these materials, however, is only half the challenge. The other half is to develop a methodology for conducting performance-based LCAs in order to capture the circular benefits of MBCs and accurately compare them to conventional material alternatives.

Life-cycle Assessment (LCA)

A typical LCA is cradle-to-gate, meaning that the scope of the assessment spans from the production of the material up to the factory gate. However, the unique strengths of mycelium-based materials are their locality as well as their circularity. Therefore, this research conducts a cradle-to-cradle LCA which is made possible by specifying an application of interest.

Application-based Comparison

The most common functional unit for LCA is a set quantity or weight. However, this fails to consider the material’s performance. In order to evaluate whether mycelium is a better material for temporary falsework than plywood or cardboard, a finite element model (FEM) is used to first optimise how much material would be required to support the same modular concrete block. In this way, the performance is equalised and material quantity optimised in order to then provide a performance-based comparison metric.

Feasibility and Testing

The BIO Lab Table illustrates how the properties of MBC can be altered by the production method. The foam-like mycelium (see Regional Comparison samples) can be used as thermal insulation or as acoustical insulation materials, but not for structural applications. However, heat-pressing at the end of the production increases their mechanical performance to values similar to those of plywood. Combining these into a mono material for partition wall applications could provide a circular alternative to the standard partition constructions we rely on today.

Diagram showing the possible Life Cycle for a mycelium-based material.

Cycles and Districts / [BIO] Urban Biocycles Mycelium Digitalisation

Selina Bitting, Tiziano Derme, Serban Bodea, Eugene Soh, Jia Heng Teoh, Nazanin Saeidi, Alireza Javadian, Hortense Le Ferrand, Dirk Hebel, Benjamin Dillenburger, Philippe Block